Otoklav

Italmatic, 1966 yılından bugüne İtalya’da üretim yapmaktadır ve sahip olduğu geniş vizyonla otoklav üretiminde önde gelen üreticilerden biri olmuştur. Mühendislik çalışmaları, kaliteli üretim ve satış sonrası servis desteğine verdiği önem Italmatic’i bugün geldiği noktaya taşımıştır.

Otoklavlar için gerekli kontrollerin geliştirilmesi ve hazırlanması için ihtiyaç duyulan yazılım ve donanım konularında uzmanlarla çalışılmakta ve güvenlik ön planda tutulmaktadır. Bütün otoklavlar CE ve 97/23 PED güvenlik sertifikaları ile ilgili uluslararası kuralları tam olarak karşılayacak şekilde tasarlanmış ve üretilmiştir.

Otoklav

Otoklav

Otoklav

Genel Özellikler

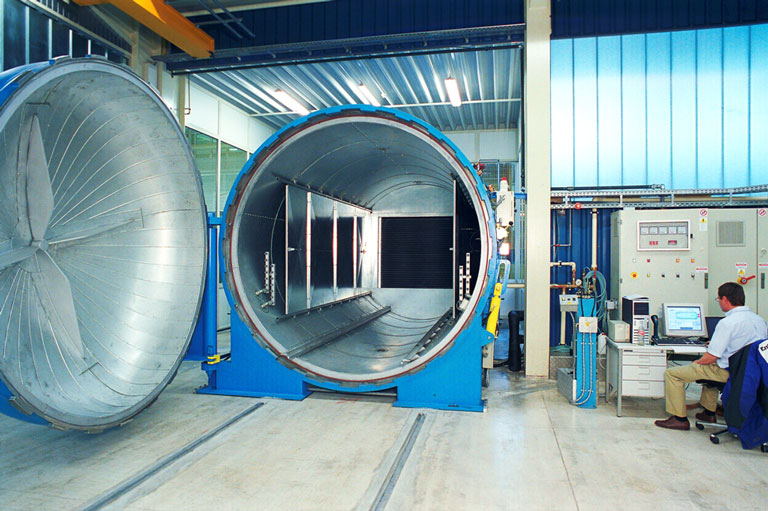

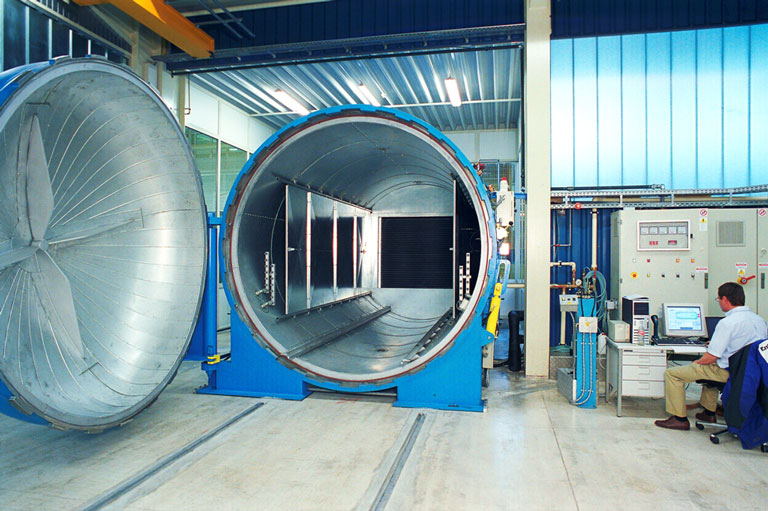

Italmatic Otoklavları sıcaklık, basınç ve vakumun kontrol anlatında tutulduğu ve lamine edilecek camlar için kullanıldığı özel cihazlardır. Fan ve uygun kanallardan oluşan özel hava geri dönüşüm sistemi ile basınç ve sıcaklığın otoklav içinde homojen olarak dağılması sağlanır.

Sıcaklık, ısıtma, bekletme ve soğutma aşamalarında ayrı ayrı kontrol edilir. Isıtma / soğutma bölümünde sıcaklık değişimi müşterinin ihtiyaçlarına göre belirlenir.

Italmatic, otoklavın çalışması için gerekli tüm yardımcı hizmetleri sağlayabilir. Doğrudan satın alması durumunda müşterisine gerekli servisi verebilir.

Otoklav kullanımı için gerekli ek ihtiyaçlar:

- Basınçlı Hava

- Soğutma Tankı

- Vakum: Vakum pompası, depolama tankı ve camların işlenmesine yönelik vakum hatlarından oluşan bir istasyon vasıtasıyla elde edilir. Vakum kontrolü otomatik veya manuel yapılabilir.

- Taşıma araçları (Trolley)

Isıtma

Uygulanacak sıcaklık ve basınç kullanılan PVB’nin kalınlığına, kalitesine ve karakteristik özelliklerine göre değişim gösterebilir. Bombeli camlarda vakum torbaları kullanılıp vakumun bu tip camların her yerine uygun şekilde uygulanması sağlanmalıdır. Isı iletimi, otoklav içerisinde hava dolaşımı ile gerçekleşir. Camın kalınlığı ve miktarı maksimum sıcaklığa erişim zamanını belirler. Lamine yapılacak camların çok kalın olması durumunda, ısıtma evresinde istenilen sıcaklığa ulaşana kadar birkaç kez ara verilmesi önerilmektedir.

Bekleme

Bekleme süresi, otoklavdaki sıcaklık, basınç ve uygulanan vakumun sabit tutulduğu zamandır. Bekleme safhasındaki basınç 13 Bar'dır.

Soğutma

Bu aşamada otoklav içinde bulunan lamine cam soğutulur. Basınç belli değerlerde sabit tutulur. Gerekirse vakum kesilebilir. Kullanılan filmin özelliğine göre bu karar verilir. Soğutma tamamlandığında hava ile basınç dengelemesi yapılır.

Kontrol Sistemi

Kontrol sistemi, sürecin otomatik yönetim için PLC ve sistemin denetimi için dokunmatik ekran ve PC’den oluşmaktadır.

Sistem aşağıda belirtilen özelliklere izin veren uygulama yazılım paketini temel almaktadır:

- Üretim şarjı için reçeteyi ekleme ve saklama

- Uygun video sayfaları vasıtasıyla devam eden döngünün işlem verilerini görselleştirmek ve müdahale etmek (sinoptik otoklav, video sıcaklık sayfaları, basınç,vakum,etc.)

- Çalışma döngülerini izlemek ve tekrarlamak için gerekli tüm verileri kaydetmek

- Nihai sistem alarmlarını doğrulama ve geri yükleme

- Seçilebilen numune termocouple ile çalışma döngüsünü otomatik olarak kontrol etme

- PLC+ dokunmatik ekran (Temel sistem)

- PLC+ denetimli dokunmatik ekran (Özel)

- PLC+ PC denetimli (Özel)

WEB

BROŞÜR 1

BROŞÜR 2

Autoclave

Italmatic is a leading producer of autoclaves established in 1966 and managed with a long term vision and approach. Industrial electromechanical competencies historically developed into engineering, production, commissioning and post sales service support for turn-key plants for tyre rethreading. Production centralized in Italy, to maximise synergies, control of the quality, research and development.

The development and preparation of running controls for the autoclaves are executed internally through companies skilled in software and hardware solutions, being part of Italmatic group, as a warranty of the max. assistance in a long term optic.

Italmatic brand is synonym of quality of products and services offered to its own Customers. In fact, quality in Italmatic is very important and subject of important and continuous investments. The production of balancing weights is certified ISO 9001 and ISO TS (certification requested by car OEM). Analogously, design and construction of autoclaves, solid tyres, rubberizing of metal cylinders and similar are certified ISO 9001. Moreover, all of our autoclaves are designed and produced to reflect fully the most severe international rules about safety CE and 97/23 PED.

Otoklav

Otoklav

Otoklav

Glass Lamination

The assembling of two or more glass sheets with a laminated plastic film interposed between them, after being adequately handled in autoclave, is called STRATIFIED GLASS. Of large use, and more and more requested by the market by virtue of the more restrictive norms in subjects like stoutness and security, are tempered glass, tempered/toughened, both flat and curved, up to break-through proof and bullet-proof glasses. Therefore, it can be easily understood how the kind of assembling, of laminated plastic (PVB) and above all the polymerization treatment inside the autoclave are of essential importance to obtain a product of good quality. In fact, the use of ITALMATIC autoclaves allows obtaining the desired quality of the product. The reliability and the precision of the cycles in autoclave allow to reach and keep high quality standards of the product.

General Features

Italmatic Autoclaves are hyperbaric chambers where temperature, pressure and vacuum are controlled. By means of a special air recycling system, consisting of a fan and suitable ducts, the homogeneity of pressure and temperature is obtained. It is possible to heat the autoclave by means of an electric battery, or by diathermic oil or steam.

Temperature is checked in phase of heating, keeping and cooling. The heating/cooling gradients are established according to the specifications requested by the customer. Pressure is adjusted in pressurization, keeping and release phases, by means of pneumatic modulating valves that, run by the control system, let the air needed for the cycle get in or out. Italmatic can supply all the auxiliary services necessary to the functioning of the autoclave or support the customer in case of direct purchase of the same.

The necessary auxiliary services are:

- Compressed air: obtained by means of a rotative screw compressor with storage tank.

- Cooling water: obtained by means of:

- Evaporative tower at open circuit

- Further solutions like evaporative towers, exchanger cool water/air, etc.

- Heating (not foreseen for autoclaves with electrical heating): obtained by means of:

- Heater at diathermic oil with open circuit powered with gas or other combustible.

- Steam heater powered by gas or other combustible.

- Vacuum: obtained by means of a group or station, made up with vacuum pump, storage tank, and vacuum lines for the treatment of glass in envelopes; the vacuum control can be done automatically or manually.

- Material loading/unloading: it is carried out by means of trolleys with under-trolleys, translation systems or trolley rotation, complete with sliding rails.

Heating

Temperature and pressure are raised following 2 independent gradients which are typical for the used PVB thickness, quantities and characteristics.

During the treatment of curved stratified glass in the heating and pressurization phases, the material is protected by suitable bags and kept inside them in vacuum conditions, to favour the outlet of eventual air bubbles trapped among the layers of glass and PVB.

The heat transmission occurs with the exchange of air circulating inside the autoclave.

The thickness and quantity of the glass determine the necessary time to reach the max. temperature of the cycle inside the stratified glass. We suggest, to check the cycle, to use sample pieces equipped with probes similar in their structure to the material to be produced.

In case of very big thickness of laminated glass sheets it is suggested to make some breaks during the heating phase to uniform temperature.

Keeping

The keeping period is the time in which temperature and pressure in the autoclave and eventually vacuum in bags containing the stratified curved glass are kept constant. The pressure reserved during the keeping phases is 13 Bar.

Cooling

In this phase the laminated glass contained inside the autoclave is made cold. The forced circulation of air and the low temperature of the water-air exchanger allow following and satisfying the fixed cooling gradients. Pressure is kept constant according to the fixed value. In this phase the vacuum can be interrupted (it depends on the features of the plastic film). Once the final cooling temperature is reached, the air used to pressurize the autoclave is released. The release time can be grammed; we suggest to carry it out in a considerably long time, in order not to cause stress to the glass that has just been stratified. Automatic system of vacuum lines If required, it is possible to install an automatic vacuum plant that, run by the control system, allows the extraction of the air residues remained trapped during the assembling phase of the stratified glass.

Control System

The control system was expressly studied and developed for the glass field and it is made up of one PLC for the automatic managing of the process and of one TOUCH SCREEN or PC for the supervision of the system. The regulation system is based on an applicative software package which allows to:

- insert and store the productive cycles recipes

- visualize and intervene on the process data of the ongoing cycle through appropriate video pages (synoptic autoclave, video temperature pages, pressure, vacuum, etc.)

- register all the data necessary to trace and repeat the various working cycles on printer or register with more channels

- verify and restore eventual system-alarms

- make automatically check the functioning cycle through sample thermocouples which can be selected (automatic control air/pieces). The above described system is modular and expandable allowing at any moment to enlarge the number of the signals to be managed with relation to the plant developments without substituting the whole control system. It is possible to install systems according to the specifications requested by the customer and developed in various configurations:

- PLC + touch screen (base system)

- PLC + touch screen with supervision (dedicated)

- PLC + PC with supervision (dedicated)

| Dimension Size mm. | 1700x4500 | 2100x4500 | 2600x5000 | 3000x6000 | 3300x7500 | 3800x7500 | 4000x7500 |

| Shell Ins. diam. | 1700 | 2100 | 2600 | 3000 | 3300 | 3800 | 4000 |

| Shell Length | 4500 | 4500 | 5000 | 6000 | 7500 | 7500 | 7500 |

| Max. height - Glass Length | 1200x3210 | 1600x3210 | 2200x3210 | 2600x4500 | 2800x6000 | 3210x6000 | 3210x6000 |

| Temperature C° | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| Max. Pressure | 13 | 13 | 13 | 13 | 13 | 13 | 13 |

| Heating with diathermic oil, electrical, steam | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

WEB

BROŞÜR 1

BROŞÜR 2